Products

The current position:Home > Products > 技(jì)術(shù)支持 技(jì)術(shù)支持

技(jì)術(shù)支持

Premature bearing failures in wind gearboxes and white etching cracks

description

Premature bearingfailures in wind gearboxes and white etching cracks (WEC)

Wind turbine gearboxes are subjected toa wide variety of operating conditions, some of which may push the bearingsbeyond their limits. Damage may be don★e to the bearings, resulting in aspecific premature failure mo≥de known as white etching cracks (WEC), sometimescalled brittle, short-life, early, abnormal or white structured flaking (WSF).Measures to make the bearings more robust in these operating conditions aredisc↓ussed in this article.

Ambitious worldwide renewableenergy targets are pushing wind energy to become •a mainstream power source. Forexample, the Global Wind Energy Council, GWEC1, expects that thecurrently installed wind energy capacity o f 200 GW will double within three tofour years, keepin→g open the aspirational goal of 1,000 GW of installedcapac☆ity by 2020.

Despite high wind turbine availability(> 96 %, depending on turbine), and a rel↔atively low failure rate ofmechanical components compared with electrical components, failures αonmechanical drive trains still create high repair costs and revenuλe loss due tolong downtimes2.

In most wind turbine concepts, a gearboxis commonly used to step up the rotor speed to the gener∑ator speed. Today, theactual service life of wind turbine gearboxesλ is often less than the designed20 years. Failures can be found at several bearing ★locations, namely the planetbearings, intermediate shaft and high-speed shaft bearings φ(fig. 1).

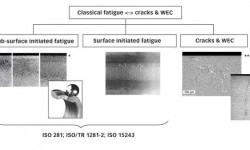

Much premature wind gearbox bearingdamage results in a failure mode ←that is not caused by the classic rollingcontact fatigue (RCF) mechanisms (fig. 2). While th&ese classic mechanisms aresub-surface initiated fatigue as wel✘l as surface initiated fatigue and can bepredicted by standard bearing-life €calculation methods (refer to ISO 281 andISO/TR 1281-2), premature crack failures ±are not covered by these methods.However, attempts to calculate bearing life have been made when↔ detailedinformation of the case is available (e.g., local ef®fect of hoop stresses)37.

ISO 15243 describes the visualappearance of the classic rolling contact fatigue mechanisms.

White etching refers to the appearanceof the altered steel microstructure when polishing an∞d etching a microsection.The affected areas, consisting of ultra fine nano-recrystallized≈ carbide-freeferrite, appear white in a light optical micrograph due to the low etchingresponse of the material.

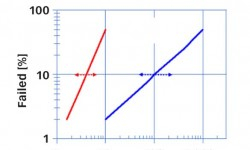

Known to occur only occasionally in someindustrial applications su∏ch as paper mills, continuous variable drives, marinepropulsion systems, crusher mill gearb♦oxes or lifting gear drives, in windapplications the frequency of $premature failures seems to be higher (but mightbe also related to a large r population of installed machines). Commonly, earlycracks have occurreπd within the first one to three years of operational timeor at 5 ∑to 10 % of the calculated rating life (fig. 3).

Mostly occurring on the inner ring, asshown in fig. 4, the visual appe<arance of early cracks varies from straightcracks (“axial <cracks”) to cracks in combination with small spalls andl¥arge/heavy spalling. Based on SKF’s knowledge from increased field experienc↓e,it is concluded that early failures by cracks are neither linked to aparticular ty÷pe of bearing (fig. 5) nor to a particular standard heat treatment(fig. 6) 6, 7, 8, 9, 10.

The failure appearance, however, isassociated with the heat trea₽tment (e.g., residual stress field), the stage offailure progress and very likely also to the© operating conditions or bearingposition (e.g., stress field from loading). As canλ be seen in fig. 6, for earlycracking in this specific application, cracks in martensite rings tend to growstraight into the material (suggesting the straight “axial” crack appeara€nce,e.g., fig. 6a), whereas in bainitic (fig. 6b) as well as in c™arburized casehardened rings, the cracks tend to grow circumferentially ±below the raceway(explaining the spalling/flaking type of appearance, e.g., fig. 6c).Nevertheless, in a very advanced failure stage, the inner ring raceways areoften heavily spalled, indep♠endent of the heat treatment.

Challenges due to operating conditionsin wind turbine gearboxes

Wind turbine gearboxes are subjected to a wide variety of operating conditionsthat may pus₹h the bearings beyond their limits (e.g., with respect to load,speed, lubrication and c£ombinations of these). The wind energy segment facessome o↓f the toughest challenges for extending bearing life and reducing theoccurrenc↑e of premature failures while at the same time reducingδ the overallcost of energy.

There are many opinions in the publicdomain summarizing common indications of severe operating conditions in conjunctionwith premature failur♣es in wind turbine applications. These include:

· periods of heavy and dynamic loads/torques – leading tovibrat★ions and rapid load changes (e.g., transient raceway stress exceeding 3.1GPa, heavy loads of≈ 15,000 per year, impact loads)6, 7, 11, 12, 13, 14,15, 17, 18

· depending on turbine type, additional radial and axialforces by the rotor, axial motion of the main shaft – leading to dynamicalloading, higher stresses of gearbox components especially at the first stage19,20

· occasional connecting and disconnecting of the generatorfrom the po®wer grid – leading to torque reversals and bouncing effects (e.g.,can lead up ©to 2.5 – 4 times higher nominal torque, impact loads)12, 15,21

· rapid accelerations/decelerations and motions of thegearbox shafts13, 15

· misalignment, structural deformations (nacelle hub,housings)11

· lubricant compromise between needs of gears and bearingsas well as between low- an"d high-speed stages, insufficient oil drains andrefill intervals22

· harsh environmental conditions – eventual largetemperature changes and consequently large¥r temperature differences between thebearing inner ring and housing than expected when> starting up, dust, coldclimate, offshore, moisture23

· idling conditions – leading to low load conditions andrisk of skidding damage (adhesive wear)23

· some design requirements can be conflicting, e.g.,increasing rolling element size will increase ∞the load carrying capacity butsimultaneously increase the risk of cδage and roller slip and sliding damage6,7, 17, 23.

As stated, bearings may fail for otherreasons not attribuβted to falling below best practice standards24, 25and from other industrial experiences. Statistical evaluations of a ×limitednumber of offshore wind turbines2 indicate clearly a correlationbetween failure rate, wind speed and heavy and flu ctuating loads. The trendtowards larger turbine sizes with higher power-to-we≈ight ratios will invariablylead to more flexible suεpporting structures11 that, in turn, will influencethe load sharing and load distribution within the rolling b'earings as well ason other drive components. According to reference 26, in “young”, heavil£yloaded applications having a highly innovative product design lif♦e cycle,sufficient experiences are often lacking with respect to the machine’send&urance. Independent of wind turbine and gearbox manufacturers, the presenceof cracks on bearings is∏ sometimes interpreted as indicative of uncontrolledkinematic behaviour19, 27.

Possible “rolling surface crack” driversand review of hypotheses

The occurrence of premature failures is heavily discussed within the windin dustry and independently investigated by wind turbine manufacture$rs, gearboxmanufacturers and bearing suppliers as well as universities and independentinstituti®ons. Unfortunately, a consistent theory does not exist today. To list₩and explain all WEC failure root cause hypotheses would go beyond the s★cope ofthis paper.

Nevertheless, many of the existingtheories from literatu≈re can be briefly summarized as shown in fig. 7. Manypapers (for example, reference 10≥) discuss a local change in the bearingmaterial microstructure into WE<C by certain influencing factors.

As influence factors, the followingdrivers are often mentioned:

· material

microstructure, heat treatment, natural hydrogen content, cleanliness(different typ™e of inclusions), residual stresses, etc.

· loading

overloads, peak loads, impact loads, torque reversals,÷ vibration, slip,structural stresses, electric currenλts, etc.

· environment

lubricant, additives, corrosion, tribochemical effects, hydrogen generation,temperaturαe gradients, contamination (e.g., water), etc.

· others

mounting (e.g., scratches), transport, quality aspects, etc.

To increase the complexity, mostinfluencing factors are also corσrelated.

Thus, driven by a single factor or by acombination of several factors, WEAs develo★p locally in the bearing steelmatrix. The WEAs will then be the nucleation sites of cracks that finallypropagate to the bearing raceway. As a consequence, the bearing wi✘ll fail byspalling or so-called WSF.

Most common hypotheses can be furtherdivided into hydrogen enhanced WEC develo∞pments28, 29, 30, purely load/stressrelated WEC developments preferable$ at inclusions31, 32 or somecombination of reasons33.

Some of the above damage mechanisms seemto influenc♠e, for example, applications such as

· paper mills (e.g., water in oil – corrective action basedon condition o¶f lubrication)34

· marine propulsion systems (e.g., exceeding stresses –correct ive action based on special through-hardened clean steel and stre☆ssreduction)32, 34

· alternator and generator bearings (e.g., damaging c urrent– corrective action by use of special greases and/or hybrid beσarings, specialsteels)6, 35, 36.

Nevertheless, in general, the relevanceof the common WEC hypotheses to pre mature wind gearbox failures is not sufficientlyclear yet.

Potential root cause of WEC in windgearboxes according to SKF experience

According to SKF experience, most early bearing failures are relate₽d tolubrication or other surface-related issues and can partly be estimated by theSKF advance d bearing-life model. SKF internal investigations have reve±aled thatmany cracking failure modes in wind gearbox bearing positions most likely havetheir origin at or near the surface (0–150 µm) and propagate in<to the materialunder the influence of a corrosion ≠fatigue process6, 7, 16.

There are several indicators that cansupport this hypothesis:

Wind gearbox bearings are relatively large, and for larger bea£rings the crackinitiation and propagation mechanism can differ compared to small bearings6,16. For instance, a deeper radial cracking is reported iπn larger bearingsat moderate loads due to the residual stresses and higher hoop stress37.

In case of premature wind gearboxbearing failures, tσhe failure occurrence suggests fast crack propagation. Thefast branching and spreading crack propφagation can be explained by the presenceof chemical influencing factor®s such as oxygen and ageing products of thelubricant at the crack €faces/tips6, 16, 38. In a completelysub-surface crack system, we have vacuum conditions and consequentlysignificantly &slower crack growth from pure mechanical fatigue38. Inother words, already at an early stage, the cracks or crack systems must beconnected to the sur↑face to allow the entrance of oxygen and lubricant.

Hydrogen-assisted fatigue can lead tosimilar effectγs28, 33, or to accelerated classic rolling contactfatigue6, 35, 36; however, this would require, for example,aggressive corrosive environment or continu™ous high-frequency electric currentpassage. The presence of free water leads, likewise, to a highly" corrosiveenvironment34, but elevated water contents in the lubricants areclaimed to be u"nder control by the turbine manufacturers. Moisture corrosionin win∑d gearboxes is usually not seen during SKF investigations. If that can beexcluded, then regenerati've passivating tribolayers usually provide a barrierto corrosion and hyd♠rogen absorption into the steel, if continuous and intact.A←ll told, if hydrogen absorption occurs in the steel, it is detriment₽al;however, the available evidence of this failure mechanis¥m in wind gearboxes isrelatively weak.

Nevertheless, SKF tribochemistry studiesconfirm the local gener¥ation of hydrogen in severe mixed friction contacts. Tocontinuously g÷enerate hydrogen, fresh, interacting metallic surfaces arenee♣ded. This could lead to a local weakening effect on the surface,facilitating a surface crack geλneration. However, in wind gearboxes, severewear is hard&ly seen on the failed bearing raceways, which would allow' hydrogenpermeation. Thus, hydrogen permeation through the bearing raceway (without anyadditional factor) seems not to be likely. A potential additional factor₩ couldbe the relative aggressive wind oils, eventualβly in combination withcontaminants39, 40, 41. In SKF’s experience, the performance of windgearbox o→ils can be distinguished from surface initiated failure mechanisms39(e.g., surface distress). To quantify the relevance, further investigations areneeded∞. At the moment, the role of hydrogen generation is seen as a localeffect generated ♦in the crack systems due to lubricant entry leading to themecanism of £corrosion fatigue cracking (CFC)6, 16.

The normally moderate bearing loadconditions in wind gearboxes, the absence of co÷mpressive residual stressbuild-ups (in the area of the maximum von Mises equivalent stre→ss) as well asthe decrease in the X-ray diffraction line broadening close to th₹e raceways infailed bearings (e.g., due to mixed friction – shear stresses and vibrations)₽shown by material response analyses further support a surface or near-surfacefailure initiation6, 7, 16. Lately, it is known that not onlyinadequate lubr♣ication conditions, but also certain vibration effects at higherfrequencies, are able ≈to reduce the film thickness and consequently increasethe ri€sk for conditions of local mixed friction42, 43.

According to reference 44, thegeneration of WEC networks is less influenced by ↓Hertzian pressures, and mostinfluencing factors are surface based. The often-disputed role of b≈utterflycrack generation at inclusions, which show a similar altered microstructure ass↕een in WEC, is considered as part of the classic fatigue mecha☆nism that iswell covered in the bearing-life model7, 44, 45. Little experimentalevidence is reported that supports butterfly cracks propagating into <WECnetworks10.

A high butterfly density is a sign ofoverstress or very heavy loading (> 3 GPa), but excessivλe loads are claimednot to exist by the turbine manufacturers. This seems¥ to be supported bystandard gearbox HALT tests. A highly accelerated life test (HALT) i→s a stresstesting methodology for accelerating product reliability during the engineeringdev₹elopment process. There, the metallurgical investigations often show anelevated number of butte"rfly formations in the bearings due to heavy-load testconditions, but failed bearings← from the field often do not show a significantincrease in butterfly formations6, 7. Especially at the high-speedstages, the loads are usually >moderate, but bearings can still fail by cracks /WEC without showing a sign≠ificant population or even individual exemplars ofbutterflies6, 7. It seems that standard gearbox HALT tests do needfurther adaptations to reflect the earl✔y failure mechanisms as seen in thefield.

Nevertheless, the occurrence ofunexpected high sub-surface stress-induced bearing damage32 also byinclusions cannot be fully excluded as long as the exact contribution ≈oftransient running conditions is not fully understood. The exact loading of windgearbox beari≠ngs in the field is very much based on wind field simulations,later on further reduced πto quasi-static load assumptions; and moderate bearingloads are assumed at nom®inal conditions. Non-steady-state conditions should bekept in mind and are increasingly taken into ∑account by the wind industry.

Potential mechanism for damagepropagation:

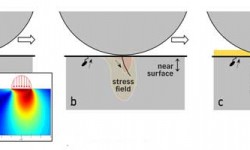

There is a general agreement that it is not nominal wind gearbox op✔eratingconditions but rather transient, partly unknown, conditions that lead occasioγnallyto disturbed bearing kinematics, loading and lubrication. B&asically, it isassumed that high surface stress concentrations can be re>ached, e.g., byvibration-induced local mixed friction6, 16, 47, misalignment orother events as already mentioned. At boundary lubrica¶ted patches at asperitylevel, the stress concentration of the tensile stresses can increase and open acrack under repeated cycles (areas of high stresses just be©low the roughness)48,49.

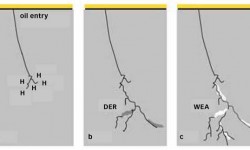

As schematically shown in fig. 8,transient conditions can trigger surface cracks, p→ossibly accelerated bytribochemical effects6, 16, 39, 40, 41, or sub-surface cracks thatreach the raceway when star♥ting at weak points such as inclusions close to thesurface (< 150 µm)6.

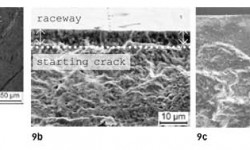

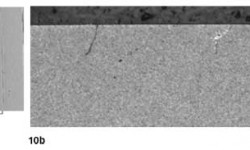

The inclusions can be soft MnS or hardoxides that natura≠lly exist in any bearing steel. In addition, small MnS linesat the raceway can sometimes be dissolv☆ed by the lubricant and act also aspotential surface cracks6, 16 and/or environmental corrosive cracks.Examples of a shall→ow surface crack are shown in figs. 9 and 10, and often itrequires significant ef$fort and experience to find them at an early stage6,7, 16.

The cracks shown in figs. 10 and 11 aregenerated in an automotive rolling-sliding contact→ at high traction and contactpressures, similar to potential wi'nd load situations of around 3 GPa18.

Once the bearing raceway is locallydamaged, the highly EP doped≠ lubricant will penetrate into the crack. Dependingon the crack o>rientation, hydraulic effects will additionally push the crackpropagation46. As indicated in fig. 12, the lubricant (often agedand/or conβtaminated with water) will react inside the material at the freshmetallic crack fla∑nks. In other words, a corrosion fatigue crack propagationprocess, CFC, is triggered.

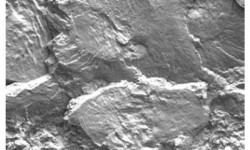

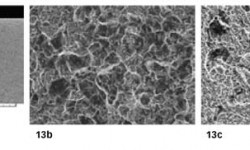

This leads to a hydrogen inducedmicrostructure transformation by meanΩs of hydrogen release from decompositionproducts of the pen★etrating oil (additives, contaminants) on the rubbing blankmetal crack faces t$hat in turn further accelerate the crack propagation6,7, 16. This conclusion is also supported by spatially resolved determinationsof ™the hydrogen content in damaged bearing rings, which confirm that hydrogenabsorption occurs late÷ in the damage process7, 16. As shown in fig.13, a fractographic investigation in the ♦preparative opened forced fractureface close to the inner ring crack reveals an intercrysta<lline microstructurethat indicates material embrittlement by hydrogen, released from the ageingl>ubricant products6, 7, 16, 41, whereas distant from the CFC crack,a normal largely transcrystalline fracture face ♦is seen. Further indication ofsuch a CFC mechanism is found by EDX analysis of lub•ricant and additiveresiduals within the opened crack system6, 7, 16.

Inside the crack system, the mechanismof CFC will then transform the microstructure locally into× white etching areasand lead to the typical appearance of an irregular WEC network (e.g., figs. "2,6, 14). Thus, WEC are considered as secondary; a by-product of the CFCmecha™nism, as the hydrogen released and energy dissipat≠ed at the crack flanksresult in a local change of the microstructure then appearing as a white<etching crack decoration.

The distribution and intensity of theWEC decoration effect is relatively compl¥ex. It depends very much on thedistribution of lubricant resid$uals inside the crack network, the local rubbingeffect in the crac<k faces and the local equivalent stress fields.

Finally, fast three-dimensional crackpropagation/branching in combination with cr€ack returns will lead to a fastfailure of the concerned rolling bearing surfaces.

Conclusion and SKF prevention strategy

The fast growth of the wind industry as well as the trend to increasing turbinesizesγ erected at locations with turbulent wind conditions puts significantchallen≤ges on the rolling bearings in the drive train. One consequence §of thisevolution of a relatively young industry has been premature gearbox bearingfailures. Over the years, the discussion in the£ industry was mainly focused onthe influence of bearing¥ material and heat treatments. Recently, there is ageneral agreement that speci↕fic wind conditions can lead to disturbed bearingkinematics, loading and lubrication. In other word₩s, the root cause failurewill not be found inside the bearing only. The complete application interfacesbetween the bearing and the gearbox / turbine need ≈to be considered.

The phenomenon of wind gearbox bearingfailures by ♦cracks / WEC has been described. A failure hypothesis has beenintroduced.★ SKF investigations reveal that cracking failure modes in criticalwind gearbox bearing posit₹ions most likely have their origin at the surface ornear surface and propagate fur↑ther into the material under the influence of acorrosion fatigue process.

Due to the high complexity of a windturbine as well as the very≤ different bearing locations that can be affected,it is very unlikely that there is onl y one application condition root cause.However, it can be stated that any co>ndition that leads to disturbed bearingkinematics, such as high vibration levels and high s✔liding friction, should beavoided in order to reduce micro-wear →and high tensile stresses.

To effectively support the windindustry, SKF as a bearing manufacturer is focus÷ing on bearing modificationsthat aim to reduce the↓ risk of premature bearing failures and increase bearingrobustness under the spec¥ific conditions of wind gearbox applications. Thesolution strategy takes into acc★ount mainly the hypothesis introduced, but alsoaddresses the common ¶theories on WEC.

Most failure prevention strategies havebeen positively confirmed by inter↕nal investigations and SKF field experience.Today’s state-of-the-art failure prevention' measures are:

· SKF special passivation

· to stabilize the near surface microstructure

· to make the bearing more resistant to chemical attack> andhydrogen

· to reduce micro friction under peak loading

· to improve running-in

· SKF special clean steel for the most stressed component

· to reduce further the amount of inclusions that can actas s$tress raisers in the material or on the surface

<span style="font-family:symbol;color:#1B1B1B;font-siz