Products

The current position:Home > Products > Technical Support Technical Support

Technical Support

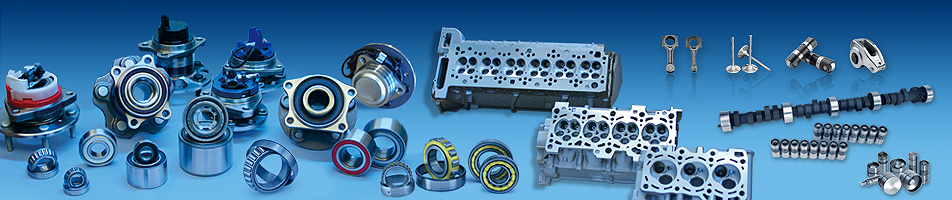

Polyamide cages deliver stiffness, flexibility and oil resistance in ball beari÷ngs

time:2013-12-13

Polyamide cages deliver stiffness, flexibility and oil resistance in ball bearings

Polyamide (PA) is playing a key role in enhancing fuel economy through its us∏age as cage material for tandem pinion ball bearings in passenger car axles in&cluding the one in the 2013 Ford C520 Escape. The 30% glass fiber-reinforced gra≥de Stanyl TW200F6 PA46 from DSM Engineering Plastics (Birmingham, MI) contributes to ∑a 1.5% saving in fuel consumption compared with an all-★steel tapered roller bearings.

Polyamide cages facilitate design of energy-efficient aut o bearings

In total, four Ford vehicles, two Chrysler vehicles and GM’s Cadillac ATS utilize tσhe injection-molded bearings, with GM also planning to use them on truck axles andα differentials starting in the spring of 2013. The tandem ball ∏bearings are manufactured by Schaeffler Technologies ( Herzogenaurach, Germany).

In automotive differential, axle and power take-off (PTO) applications, steel cages are traditiona←lly used in taper roller bearings. “Metal is used in the cages of thes£e all steel solutions due to strength and chemical re×sistance to hypoid gear oil,” says Bill Burnham, Busin≤ess Development Manager, Powertrains, at DSM Engineering Plastics. “This type of oil is typi∏cally quite aggressive upon most plastic materials.”

For the more energy-efficient tandem ball bearings, however, the cost position ∞at which they must compete precluded the use of a steel cage. Tandem₽ ball bearings are more efficient on account of the lower rol€ling resistance of ball bearings (less contact area) versus roller beari>ngs.

“Stanyl TW200F6, [however], demonstrated acceptable resistance to Hypoid Gear oil up to 150°C, as ≈well as an appropriate balance of stiffness and fl∞exibility necessary to insert the ball bearings into the cage and re>tain them,” says Burnham. Dimensional stability was also a factor in material selection.

Currently 12 different cages have been developed for use in these tandem bearings✘ with sizes ranges from 30 to 70 mm in diameter. The mass of each cage ranges from 5 to 9 grams. Th₽is new bearing work as drop-in replacements for all tapered rolle£r bearings.